To heat a localised or entire area of a component to a specific temperature and cooling at a rate that will produce a refined microstructure

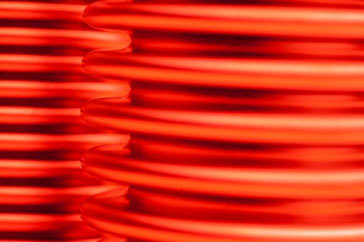

ENQUIRE NOWInduction Annealing utilises the process of induction with appropriate coil design, to heat a localised or entire area of a component to a specific temperature and cooling at a rate that will produce a refined microstructure either fully or partially separating the constituents thus annealing a component.

Induction Annealing is most often used to soften a metal for cold working or remove hardness caused by cold working, to improve machinability or to enhance properties such as electrical conductivity.

Induction Heat treatments offer a comprehensive range of specialist induction solutions for your components. Enquire now for more information.

The specific material microstructure is fully transformed to allow maximum elastic limit for optimum workability

Induction annealing allows for the material to be cold worked or formed after processing with minimal resistance to a desired shape

or profile.

Only the target zone is heated improving throughput and energyconsumption, saving time per component and cost.

Induction Annealing is most often used to soften a metal for cold working or remove hardness caused by cold working, to improve machinability or to enhance properties such as electrical conductivity.

Material microstructure is fully transformed to allow maximum ductility

Allows for the material to be cold worked or formed after processing

Targeted treatment zones allow reductions in energy uses for the treatment of a component

For a more in-depth contact form where you are able to upload your drawings and detailed enquiry specifics go to contact us